OET Press Release

Thessaloniki, Greece, June 1st, 2018: OET R&D team reached a record in power conversion efficiency to 7.4% for a fully Roll-to-Roll (R2R) printed polymer-based single junction Organic Photovoltaic (OPV) cell. Nanotechnology Lab LTFN of Aristotle University of Thessaloniki independently certified the measurement at simulated AM 1.5 illumination under 1000W/m².

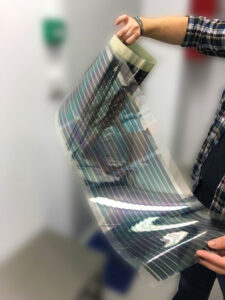

The new record 7.4% has successfully achieved for bulk heterojunction polymer: fullerene solar cells in an inverted single device stack, fully printed on a flexible substrate by R2R printing techniques based on slot die coating and inkjet printing for the various layers and electrodes involved.

This new result confirms the world-leading technology position of OET in large area printing technology and processing of fully printed single junction OPVs onto flexible substrates. OET demonstrated by its continuous progress from 1.8% in 2012 to more than 7% efficiency over the last 6 years in large area plastic substrates, supporting its road-map towards 9% for large scale OPV modules by 2021.

Thanks to its robust OPV production processes and technologies at a unique Roll-to-Roll production line integrated with the intelligent and unique capabilities of in-line optical metrologies and quality control tools, inkjet printer and an ultra – fast pulsed laser for high precision patterning and nano-structuring, OET delivers on the market high quality OPV solutions in an aesthetic way of designs for robust applications and demonstrated cases. The unique combination of R2R nano-manufacturing, in-line precision metrology, inkjet printing and low temperature pulsed laser tools and facilities were developed by a huge OET R&D investment, supported by several National Projects and by many collaborations and EU Projects such as EU FP7 Project Smartonics (www.smartonics.eu), Project Gladiator (www.graphene-gladiator.eu), the currently Running EU Projects H2020 Factory of the Future, Project SmartLine (www.smartline-project.eu) and the EU Project H2020 CORNET (www.cornet-project.eu).

Based on the support of the running H2020 projects for a robust and digital nano-manufacturing of flexible large area OPVs with tailored performance and high production yield, OET will widespread the implementation of OPVs in existing and new consumer products from Energy, Lighting, Displays and Surfaces, Electronic Circuits, all (Bio) Sensors, Wearables, ICT, IoT, etc.

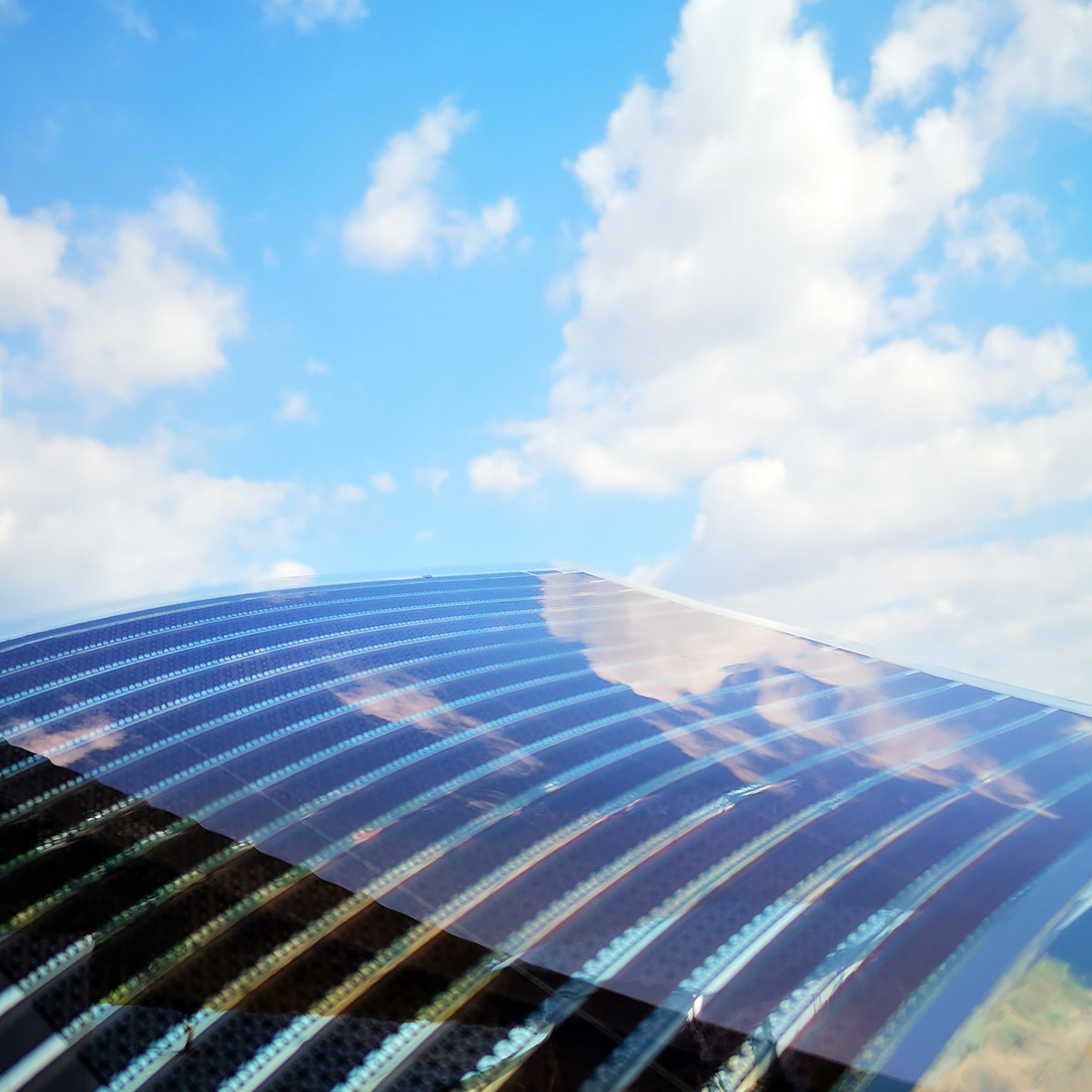

Customized fully printed OPV panels up 1 m length in a range color pallet like grey, blue, green, red, brown and shapes with a focus on client-specific requirements will be available on market in September 2018 at appealing price vary in respect to its final applications. OET’s flexible energy innovations on plastics can be adapted with simplicity to all flat and curved shaped surfaces on different electrical design assembly.

OET seeks investor support for its growth strategy plan. Mr Vasileios Matskos, CEO of OET comments: “I am very optimistic, this new result supports efforts for OPV panels mass production up to 1.000.000 m² annually, targeting various pilot demonstration projects in 2021”.

OET, founded in 2012 and located in Thessaloniki, is among the key players in the field of organic photovoltaics. In addition, OET is a world leader in large area production of fully printed OPVs with quality control. Digital closed loop manufacturing of OPV panels and devices by scalable cost efficient production processes such as R2R makes OET to stand out from its competitors. OET based on more the 25 years’ experience of its people in Thin Film technologies, delivers customized flexible OPVs in complex designs with weight <0.5kg/m², in various colors, transparencies and affordable costs.